The application of wastewater decolorizers can be said to be widely used in water treatment in modern times, but due to the different content of impurities in wastewater, the selection of wastewater decolorizers is also different. We often see some waste recycling in daily life, among which the recycling of plastics accounts for a large proportion. So what is the recycling process of these plastics and why is it related to wastewater decolorizers? Yixing Cleanwater will explain it to you.

The plastic recycling process mainly produces plastic washing, separation and wet crushing processes. The concentration of pollutants in wastewater is closely related to the properties of waste plastics used in its production. The wastewater produced by its washing and crushing processes has high organic matter and suspended solids content, among which COD can reach 2000mg/L, and SS can reach 500mg/L. The process of "grid + regulation + coagulation flotation + AO + filtration + disinfection" can be used to treat synthetic plastic production wastewater.

The sewage first flows through the grid to remove larger impurities and then enters the regulating tank. The regulating tank first has the function of homogenization and equalization, that is, to overcome the imbalance of drainage caused by uneven production (including water volume and water quality). Secondly, due to the gravity in the regulating tank, the heavy substances such as mud and sand in the sewage will settle to the bottom of the tank, which will play a clarifying role and reduce the concentration of suspended matter.

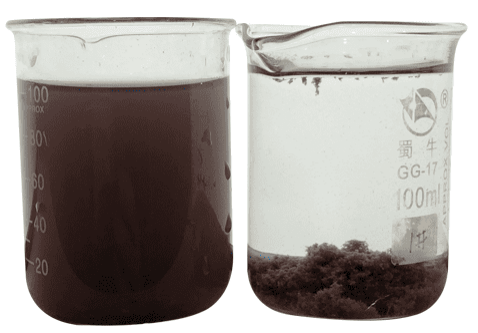

The effluent of the regulating tank is pumped to the flotation tank, which is equipped with an automatic dosing system. The sewage is added to the flotation tank, and the automatic dosing system simultaneously adds the synthetic plastic sewage decolorizer and coagulant into the flotation tank with the water flow. Under the joint action of the water flow and gas, the decolorizer and sewage are fully mixed. Through the compression of the coagulant's double electric layer and the neutralization of the charge, the adsorption bridging effect and the flocculent net capture effect, the small particles of suspended matter and colloids in the sewage are condensed into larger particles. The gas dissolved in the sewage will carry these condensed particles in the water to the water surface during the floating process and remove them through

overflow. The effluent of the flotation tank enters the biological pool in turn for biological treatment to remove most of the organic matter, ammonia nitrogen and other substances, and then separates the mud and water in the secondary sedimentation tank, and then further removes the impurities in the sewage through filtration, making the sewage more purified.

Through the above process and the use and treatment of corresponding decolorizers, the water quality of sewage is significantly improved, basically meeting the requirements of effluent water quality. Since the water may also contain harmful substances such as bacteria and viruses, the effluent must be sterilized by ultraviolet disinfection equipment before it can be discharged or reused.

Synthetic plastic sewage decolorizer has a wide range of applications:

1. It is used in oxidation, textile printing and dyeing, hardware electroplating, papermaking, pigments, oily sewage, chemical sewage, ink sewage color treatment, while reducing other pollutants in the water, reducing sewage chroma and improving effluent water quality.

2. It is also used in reclaimed water reuse, pretreatment of a small amount of high-concentration colored sewage, oil field drilling and other water treatment fields.

3. It belongs to the flocculation decolorization principle, no metal ion residue, and solves the water pollution problem at one time through mud and water separation, without secondary pollution, and the addition process is simple and adaptable.

Post time: May-20-2025