1. What are flocculants, coagulants and conditioners?

These agents can be divided into the following categories according to the different uses in the sludge press filtration treatment:

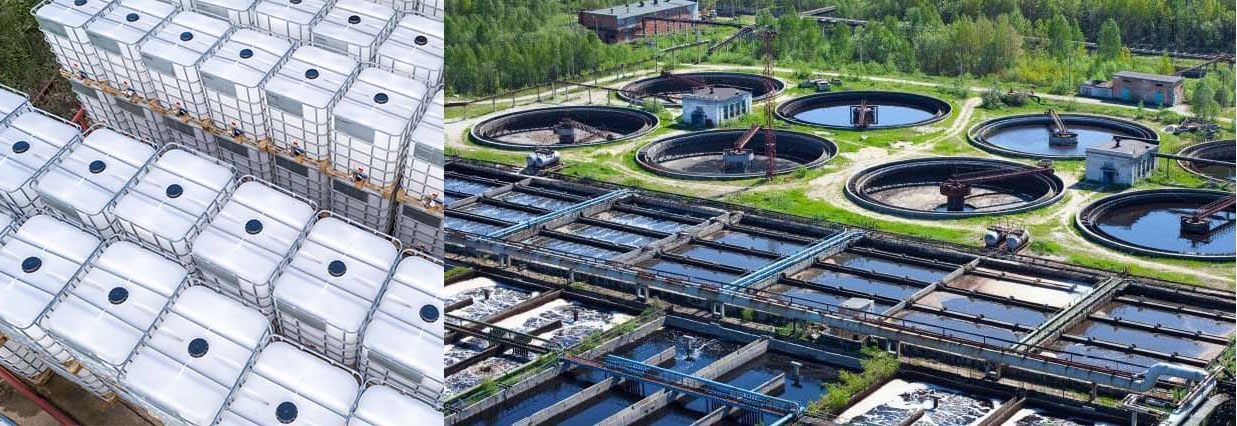

Flocculant: sometimes called coagulant, it can be used as a means to strengthen solid-liquid separation, used in primary sedimentation tank, secondary sedimentation tank, flotation tank and tertiary treatment or advanced treatment process.

Coagulation aid: Auxiliary flocculants play a role to enhance the coagulation effect.

Conditioner: Also known as dewatering agent, it is used for conditioning the remaining sludge before dewatering, and its varieties include some of the above-mentioned flocculants and coagulants.

2. Flocculant

Flocculants are a class of substances that can reduce or eliminate the precipitation stability and polymerization stability of dispersed particles in water, and make dispersed particles agglomerate and flocculate into aggregates for removal.

According to the chemical composition, flocculants can be divided into inorganic flocculants and organic flocculants.

Inorganic flocculants

The traditional inorganic flocculants are low molecular aluminum salts and iron salts. Aluminum salts mainly include aluminum sulfate (AL2(SO4)3∙18H2O), alum (AL2(SO4)3∙K2SO4∙24H2O), sodium aluminate (NaALO3 ), iron salts mainly include ferric chloride (FeCL3∙6H20), ferrous sulfate (FeSO4∙6H20) and ferric sulfate (Fe2(SO4)3∙2H20).

Generally speaking, inorganic flocculants have the characteristics of easy availability of raw materials, simple preparation, low price, and moderate treatment effect, so they are widely used in water treatment.

Inorganic polymer flocculant

The hydroxyl and oxygen-based polymers of Al(III) and Fe(III) will be further combined into aggregates, which will be kept in the aqueous solution under certain conditions, and their particle size will be in the nanometer range. Result of high dosage.

Comparing their reaction and polymerization rates, the reaction of the aluminum polymer is milder and the shape is more stable, while the hydrolyzed polymer of the iron reacts rapidly and easily loses stability and precipitates.

The advantages of inorganic polymer flocculants are reflected in that it is more efficient than traditional flocculants such as aluminum sulfate and ferric chloride, and is cheaper than organic polymer flocculants. Now Polyaluminum chloride has been successfully used in various treatment processes of water supply, industrial wastewater and urban sewage, including pretreatment, intermediate treatment and advanced treatment, and has gradually become a mainstream flocculant. However, in terms of morphology, degree of polymerization and corresponding coagulation-flocculation effect, inorganic polymer flocculants are still in a position between traditional metal salt flocculants and organic polymer flocculants.

Polyaluminum chloride, pac,msds policloruro de aluminio,cas no 1327 41 9,policloruro de aluminio,pac chemical for water treatment,poly aluminium chloride,referred to as PAC, has the chemical formula ALn(OH)mCL3n-m. PAC is a multivalent electrolyte that can significantly reduce the colloidal charge of clay-like impurities (multiple negative charges) in water. Due to the large relative molecular mass and strong adsorption capacity, the flocs formed are larger, and the flocculation and sedimentation performance is better than other flocculants.

poly aluminium chloride has a high degree of polymerization, and rapid stirring after adding can greatly shorten the floc formation time. poly aluminium chloride PAC is less affected by water temperature, and it works well when the water temperature is low. It reduces the pH value of water less, and the applicable pH range is wide (can be used in the range of pH=5~9), so it is not necessary to add alkaline agent. The dosage of PAC is small, the amount of mud produced is also small, and the use, management and operation are more convenient, and it is also less corrosive to equipment and pipelines. Therefore, PAC has a tendency to gradually replace aluminum sulfate in the field of water treatment, and its disadvantage is that the price is higher than that of traditional flocculants.

In addition, from the point of view of solution chemistry, PAC poly aluminium chloride is the kinetic intermediate product of the hydrolysis-polymerization-precipitation reaction process of aluminum salt, which is thermodynamically unstable. Generally, liquid PAC products should be used in a short period of time (solid products have stable performance). , it can be stored for a longer time). Adding some inorganic salts (such as CaCl2, MnCl2, etc.) or macromolecules (such as polyvinyl alcohol, polyacrylamide, etc.) can improve the stability of PAC, and can increase the cohesion ability.

In terms of production process, one or several different anions (such as SO42-, PO43-, etc.) are introduced in the manufacturing process of PAC, and the polymer structure and morphological distribution can be changed to a certain extent by polymerization, thereby improving the The stability and efficacy of PAC; if other cationic components, such as Fe3+, are introduced in the manufacturing process of PAC to make Al3+ and Fe3+ staggered hydrolytically polymerized, composite flocculant polyaluminum iron can be obtained.

Organic polymer flocculant

Synthetic organic polymer flocculants are mostly polypropylene and polyethylene substances, such as polyacrylamide and polyethyleneimine. These flocculants are all water-soluble linear macromolecules, each macromolecule consists of many repeating units containing charged groups, so they are also called polyelectrolytes. Those containing positively charged groups are cationic polyelectrolytes, and those containing negatively charged groups are anionic polyelectrolytes, which contain neither positive nor negatively charged groups, and are called nonionic polyelectrolytes.

At present, the most widely used polymer flocculants are anionic, and they can only play a role in assisting the coagulation of negatively charged colloidal impurities in water. Often it cannot be used alone, but is used in combination with aluminum salts and iron salts. Cationic flocculants can play the role of coagulation and flocculation at the same time and are used alone, so they have developed rapidly.

Currently, polyacrylamide non-ionic polymers are used more frequently in my country, which are often used in combination with iron and aluminum salts. The electric neutralization effect of iron and aluminum salts on colloidal particles and the excellent flocculation function of polymer flocculants are used to obtain satisfactory treatment effects. Polyacrylamide has the characteristics of less dosage, fast coagulation speed, and large and tough flocs in use. 80% of the synthetic organic polymer flocculants currently produced in my country are this product.

Polyacrylamide PAM,polyelectrolyte uses,polyelectrolyte cationic powder,cationic polyelectrolyte,cationic polymer,cationic polyacrylamide is the most widely used synthetic organic polymer flocculant, polyelectrolyte,and is sometimes used as a coagulant. The production raw material of polyacrylamide is polyacrylonitrile CH2=CHCN. Under certain conditions, acrylonitrile is hydrolyzed to form acrylamide, and acrylamide is then subjected to suspension polymerization to obtain polyacrylamide. Polyacrylamide is a water-soluble resin, and the products are granular solid and viscous aqueous solution with a certain concentration.

The actual existing form of polyacrylamide in water is random coil. Because the random coil has a certain particle size and some amide groups on its surface, it can play a corresponding bridging and adsorption capacity, that is, it has a certain particle size. certain flocculation capacity.

However, because the long chain of polyacrylamide is curled into a coil, its bridging range is small. After the two amide groups are connected, it is equivalent to the mutual cancellation of the interaction and the loss of two adsorption sites. In addition, some of the amide groups are wrapped in the coil structure The inside of it cannot contact and adsorb the impurity particles in the water, so its adsorption capacity cannot be fully exerted.

In order to separate the linked amide groups again and expose the hidden amide groups to the outside, people try to extend the random coil appropriately, and even try to add some groups with cations or anions to the long molecular chain , while improving the adsorption and bridging ability and the effect of electric neutralization and compression of the electric double layer. In this way, a series of polyacrylamide flocculants or coagulants with different properties are derived on the basis of PAM.

3. Coagulant

In the coagulation treatment of wastewater, sometimes a single flocculant cannot achieve a good coagulation effect, and it is often necessary to add some auxiliary agents to improve the coagulation effect. This auxiliary agent is called a coagulation aid. Commonly used coagulants are chlorine, lime, activated silicic acid, bone glue and sodium alginate, activated carbon and various clays.

Some coagulants themselves do not play a role in coagulation, but by adjusting and improving coagulation conditions, they play the role of assisting flocculants to produce coagulation effects. Some coagulants participate in the formation of flocs, improve the structure of the flocs, and can make the fine and loose flocs produced by inorganic flocculants into coarse and tight flocs.

4. Conditioner

Conditioners, also known as dehydrating agents, can be divided into two categories: inorganic conditioners and organic conditioners. Inorganic conditioners are generally suitable for vacuum filtration and plate and frame filtration of sludge, while organic conditioners are suitable for centrifugal dewatering and belt filter dewatering of sludge.

5.the relationship between flocculants, coagulants, and conditioners

The dehydrating agent is the agent added before the sludge is dehydrated, that is, the conditioning agent of the sludge, so the meaning of the dehydrating agent and the conditioning agent is the same. The dosage of dewatering agent or conditioning agent is generally calculated as a percentage of the weight of the dry solids of the sludge.

Flocculants are used to remove suspended solids in sewage and are important agents in the field of water treatment. The dosage of flocculant is generally expressed by the amount added in the unit volume of the water to be treated.

The dosage of dehydrating agent (conditioning agent), flocculant, and coagulation aid can be called the dosage. The same agent can be used as a flocculant in the treatment of sewage, and can be used as a conditioner or dewatering agent in the treatment of excess sludge.

Coagulants are called coagulants when they are used as flocculants in the field of water treatment. The same coagulants are generally not called coagulants in the treatment of excess sludge, but are collectively referred to as conditioners or dehydrating agents.

When using a flocculant, since the amount of suspended solids in the water is limited, in order to achieve full contact between the flocculant and the suspended particles, mixing and reaction facilities need to be equipped with sufficient time. For example, mixing takes tens of seconds to several minutes, The reaction requires 15 to 30 minutes. When sludge is dewatered, it usually takes only a few tens of seconds from when the conditioner is added to the sludge entering the dewatering machine, that is, only the mixing process equivalent to the flocculant, and there is no reaction time, and experience has also shown that the conditioning effect will increase with the stay. decreased over time.

Well-run tools, qualified sales crew, and superior after-sales providers; We are also a unified huge spouse and children, all people keep on with the corporate value “unification, devotion, tolerance” for 100% Original Factory China Apam Anionic Polyacrylamide PAM for Crude Oil Petroleum, Yixing Cleanwater Chemicals Co., Ltd. has experienced manufacturing facilities with more than 100 employees. So we can guarantee short lead time and quality assurance.

Buy more and save more 100% Original Factory China Anionic Polyacrylamide,chitosan, drilling polymer, pac,pam,decoloring agent,dicyandiamide,polyamines,defoamer,bacteria agent,Cleanwat will continue to adhere to the ” superior quality, reputable, the user first ” principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

Excerpted from Bjx.com

Post time: Jul-09-2022