Flocculant is often referred to as "industrial panacea", which has a wide range of applications. As a means of strengthening solid-liquid separation in the field of water treatment, it can be used to strengthen the primary precipitation of sewage, flotation treatment and secondary precipitation after activated sludge method. It can also be used for tertiary treatment or advanced treatment of sewage. In water treatment, there are often some factors that affect the coagulation effect (dosage of chemicals), these factors are more complex, including water temperature, pH value and alkalinity, the nature and concentration of impurities in water, external water conservancy conditions, etc.

1. Influence of water temperature

Water temperature has a significant impact on drug consumption, and low temperature water in winter

has a greater impact on drug consumption, which usually leads to slow formation of flocs with fine and loose particles. The main reasons are:

The hydrolysis of inorganic salt coagulants is an endothermic reaction, and the hydrolysis of low temperature water coagulants is difficult.

The viscosity of low-temperature water is large, which weakens the Brownian motion of impurity particles in

the water and reduces the chance of collision, which is not conducive to the destabilization and aggregation of colloids and affects the growth of flocs.

When the water temperature is low, the hydration of the colloidal particles is enhanced, which hinders the cohesion of the colloidal particles, and also affects the adhesion strength between the colloidal particles.

The water temperature is related to the pH of the water. When the water temperature is low, the pH value of the water increases, and the corresponding optimal pH value for coagulation will also increase. Therefore, in winter in cold regions, it is difficult to obtain a good coagulation effect even if a large amount of coagulant is added.

2. pH and Alkalinity

The pH value is an indicator of whether the water is acidic or alkaline, that is to say, an indicator of the H+ concentration in the water. The pH value of the raw water directly affects the hydrolysis reaction of the coagulant, that is, when the pH value of the raw water is within a certain range, the coagulation effect can be guaranteed.

When the coagulant is added to the water, the H+ concentration in the water increases due to the hydrolysis of the coagulant, which causes the pH value of the water to drop and hinders the hydrolysis. To keep the pH within the optimal range, the water should have enough alkaline substances to neutralize the H+. Natural water contains a certain degree of alkalinity (usually HCO3-), which can neutralize the H+ generated during the hydrolysis of the coagulant, and has a buffering effect on the pH value. When the alkalinity of the raw water is insufficient or the coagulant is added too much, the pH value of the water will drop significantly, destroying the coagulation effect.

3. Influence of the nature and concentration of impurities in water

The particle size and chargeability of SS in water will affect the coagulation effect. Generally speaking, the particle diameter is small and uniform, and the coagulation effect is poor; the particle concentration in the water is low, and the probability of particle collision is small, which is not good for coagulation; when the turbidity is large, in order to destabilize the colloid in the water, the required chemical consumption will greatly increase. When a large amount of organic matter exists in the water, it can be adsorbed by the clay particles, thus changing the surface characteristics of the original colloidal particles, making the colloidal particles more stable, which will seriously affect the coagulation effect. At this time, an oxidant must be added to the water to destroy the effect of organic matter , improve the coagulation effect.

Dissolved salts in water can also affect the coagulation effect. For example, when a large amount of calcium and magnesium ions exist in natural water, it is conducive to coagulation, while a large amount of Cl- is not conducive to coagulation. During the flood season, high turbidity water containing a large amount of humus enters the plant due to the scouring of rainwater, and the pre-chlorination and coagulant dosage generally used are based on this.

4. Influence of external water conservancy conditions

The basic conditions for the aggregation of colloidal particles are to destabilize the colloidal particles, and to make the destabilized colloidal particles collide with each other. The main function of the coagulant is to destabilize the colloidal particles, and the external hydraulic agitation is to ensure that the colloidal particles can fully contact the coagulant, so that the colloidal particles collide with each other to form flocs.

In order to make the colloidal particles fully contact with the coagulant, the coagulant must be quickly and uniformly dispersed in all parts of the water body after the coagulant is put into the water, commonly known as rapid mixing, which is required within 10 to 30 seconds and no more than 2 minutes at most.

5. Influence of water impact load

Water shock refers to the periodic or non-periodic water shock of raw water, which suddenly changes greatly. The urban water consumption of the waterworks and the adjustment of the upstream water volume will affect the water entering the plant, especially in the peak water supply stage in summer, which makes the water entering the plant change greatly, resulting in frequent adjustment of the dosage of chemicals. And the water effect after sinking is not very ideal. It is worth noting that this change does not increase linearly. After that, pay attention to observe the alum in the reaction tank, so as not to destroy the coagulation effect due to excessive dosage.

6. Flocculant saving measures

In addition to the above factors, there are also some drug-saving measures, such as increasing the number of times of stirring in the liquid pool, reducing the precipitation of solid particles of the drug, stabilizing the drug, and saving the drug consumption.

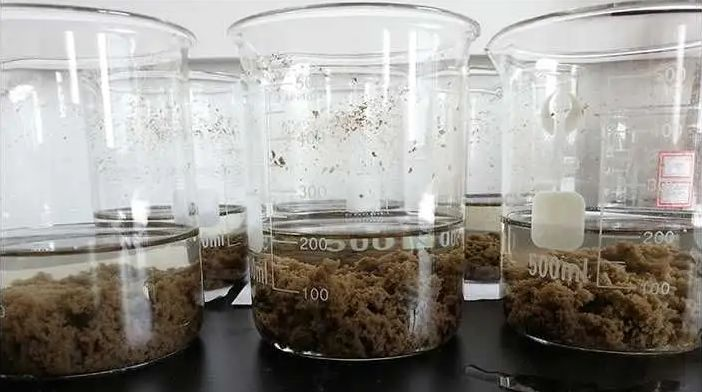

If polyacrylamide wants to save costs in use, it is necessary to choose the appropriate model. The principle is to choose the polyacrylamide with the best treatment effect, the expensive one is not necessarily the best, and don’t try to be cheap to cause poor wastewater treatment effect, but increase the cost. Select the agent that not only reduces the moisture content of the sludge, but also lowers the dosage of the unit agent. Do flocculation experiments on the provided pharmaceutical samples, select two or three kinds of pharmaceuticals with good experimental effects, and then do the on-machine experiments respectively to observe the final mud effect and determine the final pharmaceutical species.

Polyacrylamide is generally solid particles. It needs to be prepared into an aqueous solution with a certain solubility. The concentration is usually between 0.1% and 0.3%. Too concentrated or too thin will affect the effect, waste the drug, increase the cost, and dissolve the granular polymerization. The water for the object should be clean (such as tap water), not sewage. Water at room temperature is sufficient, generally no heating is required. When the water temperature is lower than 5 °C, the dissolution is very slow, and the dissolution speed is accelerated when the water temperature increases. But above 40 ℃ will accelerate the degradation of the polymer and affect the use effect. Generally, tap water is suitable for preparing polymer solutions. Strong acid, strong alkali, high salt water are not suitable for preparation.

Pay attention to the curing time in the preparation of the agent, so that the agent can be fully dissolved in water and not agglomerated, otherwise it will not only cause waste, but also affect the effect of mud production. The filter cloth and pipeline are also prone to blockage, resulting in repeated waste. Once formulated into a solution, the storage time is limited. Generally speaking, when the solution concentration is 0.1%, the non-anionic polymer solution should not exceed one week, and the cationic polymer solution should not exceed one day.

After the preparation of the agent, during the dosing process, pay attention to the change of the mud quality and the effect of the mud, and adjust the dosage of the agent in time to achieve a better dosing ratio.

The medicine must be stored in a dry warehouse, and the medicine bag should be sealed. In use, use as much as possible, and seal the unused medicine to avoid moisture. In the preparation of pharmaceuticals, care should be taken not to configure as much as possible, and the liquids that have been placed for a long time are easily hydrolyzed and can no longer be used.

Well-run equipment, specialist income crew, and better after-sales services; We're also a unified major family, anyone stay with the organization value "unification, determination, tolerance" for Quots for Polyacrylamide Flocculamide Anionic Cationic Nonionic Water Treatment Polyacrylamide, We warmly welcome buddies from all walks of everyday living to hunt mutual cooperation and build a more brilliant and splendid tomorrow."polyelectrolyte"

Quots for China Chemical and Waste Water Treatment, With the intensified strength and more reliable credit, we've been here to serve our customers by providing the highest quality and service, and we sincerely appreciate your support. We are going to endeavor to maintain our great reputation as the best merchandise supplier in the world. If you have any questions or comments, you should contact with us freely.

Post time: Nov-04-2022